Our customer, Viridian Glass in Dandenong Victoria (now Oceania Glass) contracted RMR Engineering to design, build, install and commission a Bucket Elevator for sand used in the glass making process.

The bucket elevator was approx. 33 meters above ground level with another 7 meters below, fed from a hopper unloaded into via truck transport.

At approximately 100T production per hour, and requiring zero unplanned downtime; the accuracy of delivery and design integrity were of paramount importance.

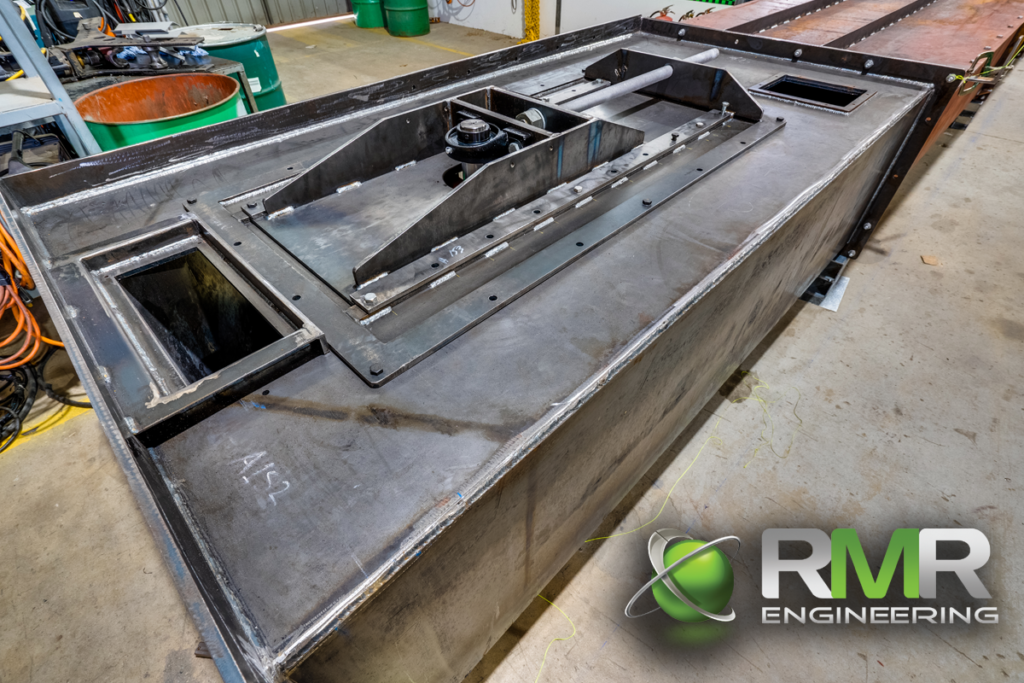

With a compressed fabrication time to meet a shutdown window, the fabrication was accelerated to ensure the shutdown was not compromised.

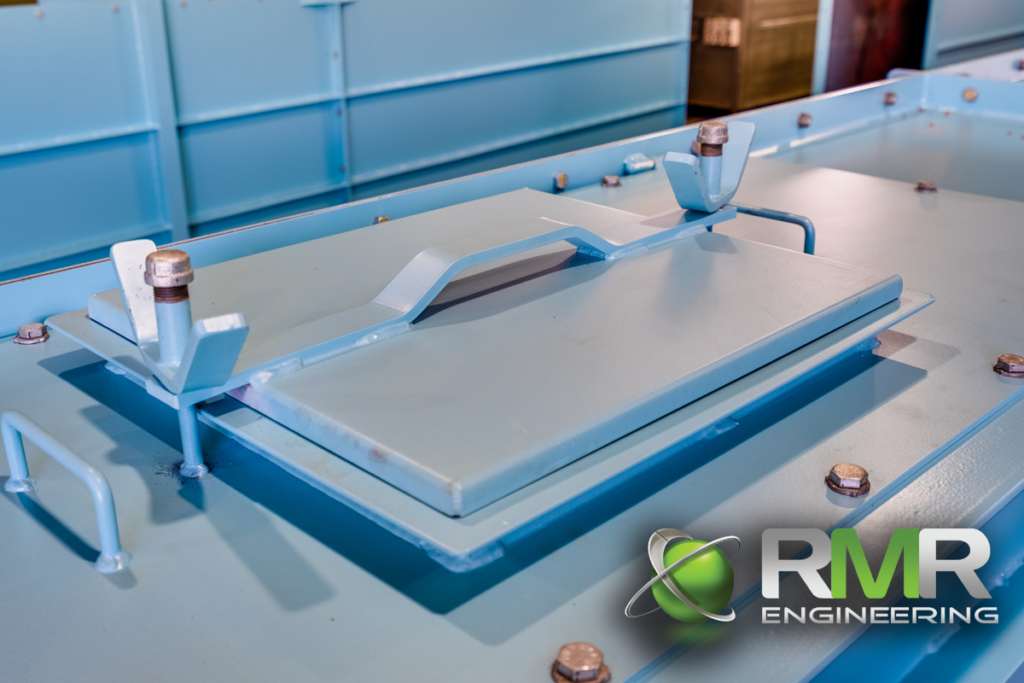

Viridian Glass made several trips to the RMR Engineering workshop to inspect the build quality and progress and were suitably impressed. The final installation had a minimal deviation.

The weather was typical Melbourne weather with 4 seasons in one day, every day, requiring several aborted starts to remove the old elevator and install the new.

The old elevator was in a sad state of disrepair, with multiple repairs completed previous to prevent water ingress, however it had reached its full life cycle by the time we became involved in this project.

Despite the compromised installation window severely affected by the weather, further impacting craneage and access hire, RMR Engineering successfully completed the installation and commissioning.

Specifications : Design Bucket Elevator

- 100-Tonne / hour capacity

- Sand Bucket Elevator

-

Designed specifically for the glass industry

- Viridian Glass was the client

- 6mm Painted Mild Steel construction

- 41.5-Mtrs in total length, standing approximately 33-Mtrs above ground level and about 8-Mtrs below ground level

- Full Design and Construct Project

- Full 3D Mechanical design drawings

- Manufacturing alignment at the final assembly was within 3mm of the 41.5-Mtrs

- Installation in Melbourne, under very trying weather conditions

- A fantastic project to be involved with, and we are now looking for our next challenge